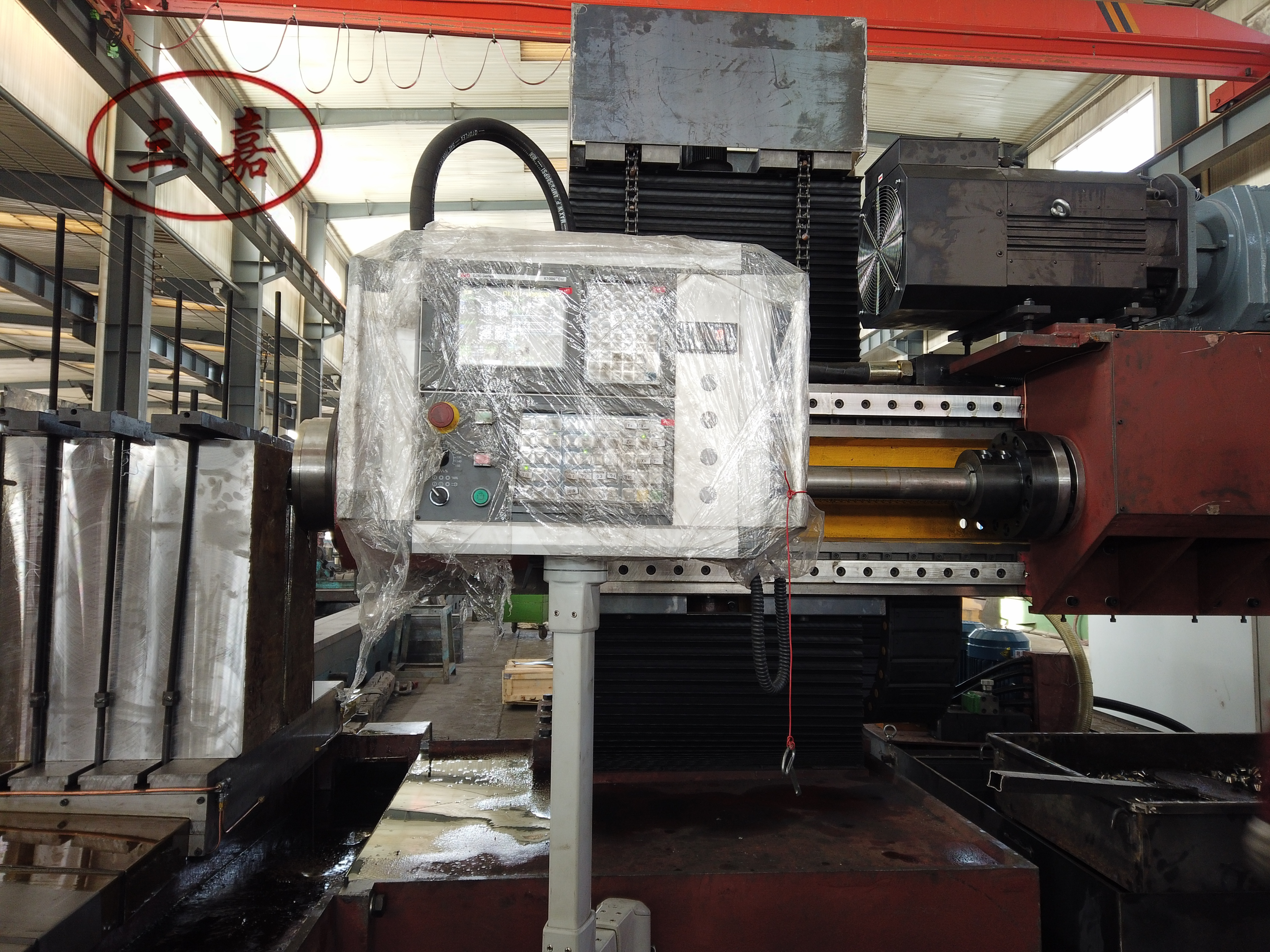

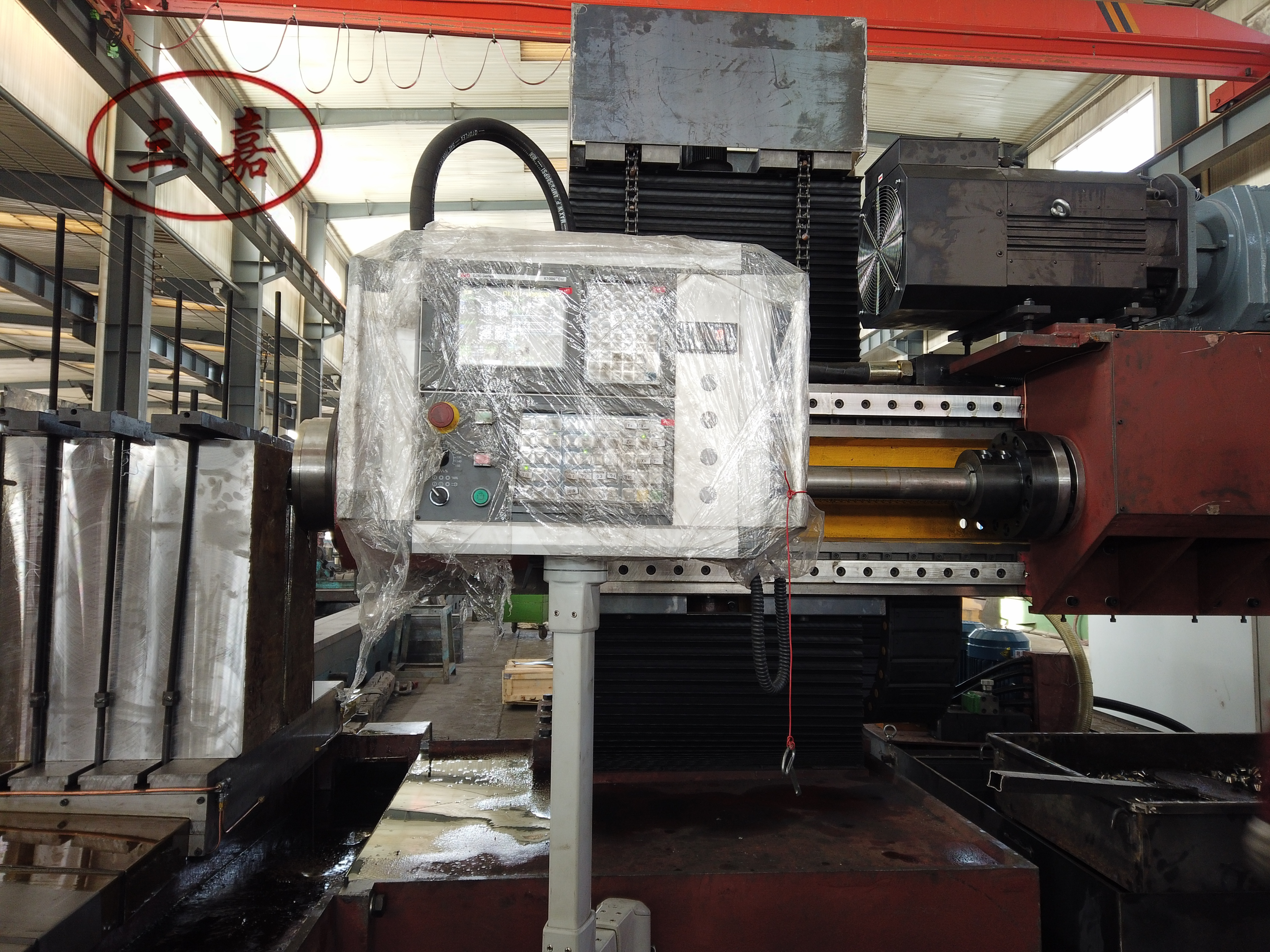

On May 5, the ZSK2320D three coordinate CNC deep hole drilling and boring machine designed and manufactured by our company completed the test run, and successfully loaded and shipped to Tianjin port.

Before delivery, all departments made a comprehensive preparation for the delivery of the deep hole drilling and boring machine to ensure that the accessories of the deep hole drilling and boring machine are complete without omission, and the quality inspection department did a good job in the final inspection before delivery. And communicate with the person in charge of the customer to ensure the normal unloading.

Machine model: ZSK2320D

Machine name: three axis CNC deep hole drilling and boring machine

Processing method: BTA drill

The machine tool has three CNC axes: an X-axis for controlling the horizontal movement of the worktable, a Y-axis for controlling the up and down movement of the sliding table, and a z-axis for feeding. On the z-axis is a set of feeding system, drill pipe box, oil feeder, and BTA bit installation.

This machine tool is designed and manufactured for processing special workpieces.

Main technical specifications of machine tools

Drilling diameter range——————————————————————— Φ 50~ Φ 90mm

Boring diameter range ———————————————————————Φ 50~ Φ 200mm

Maximum depth of drilling and boring (Z-axis) —————————————800mm

Maximum dimension of workpiece (length, width and height)——————— 800mm × 800mm× 600mm

Maximum stroke of lifting slide (Y-axis)————————————————— 600mm

Maximum stroke of worktable (x-axis)————————————————— 600mm

Dimensions of T-slot table (z) × X)—————————————————— 1000× 1200mm

Feed speed range of z-axis—————————————————————— 5~500mm/min ( (stepless)

Spindle speed range of drill pipe box —————————————————100~700r/min ( Stepless speed regulation)

Maximum bearing capacity of worktable ————————————————3000kg